1. December 2015

Prototype manufacturing…

Sembach GmbH & Co. KG extends its portfolio thanks to a new 5-axis milling machine

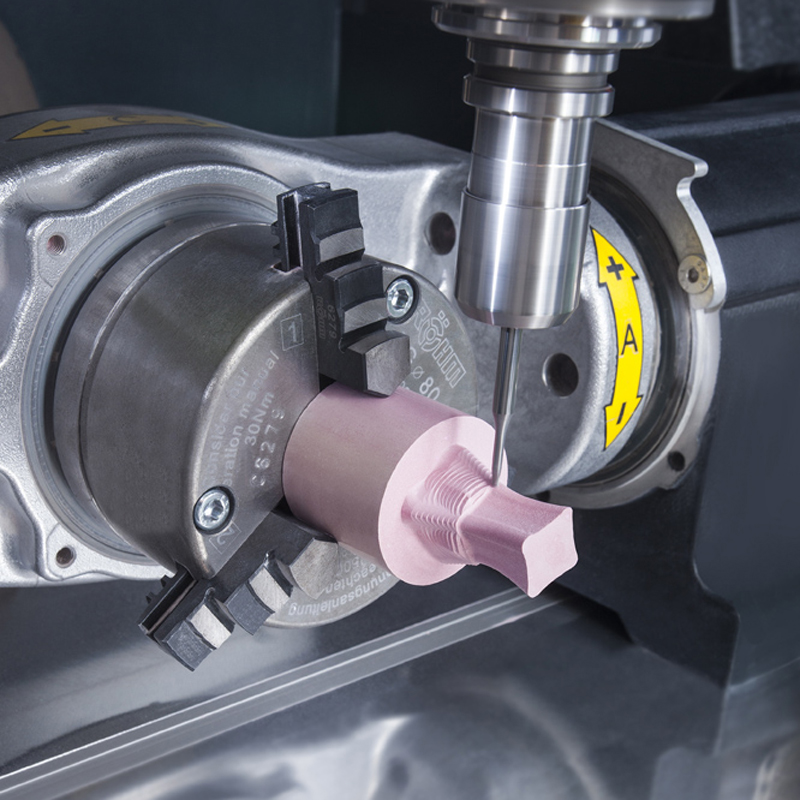

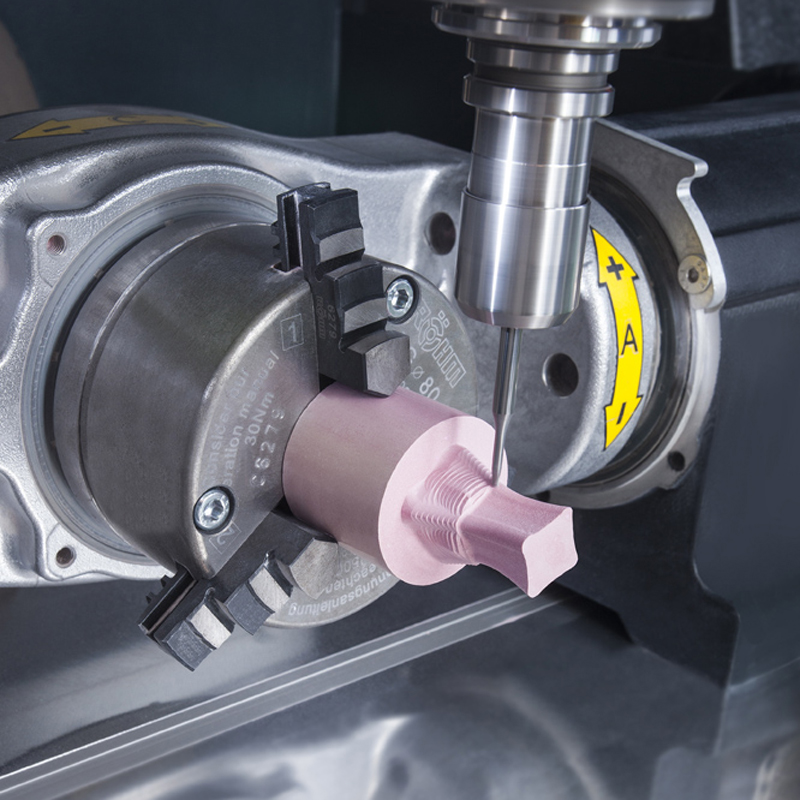

In addition to the batch production of components made of technical ceramics, Sembach Technical Ceramics has recently been in a position to offer the manufacture of prototypes and individual pieces with complex shapes as well as small batches. A 5-axis milling machine with particularly small tolerances is being used for this purpose; this eliminates the need for time consuming and cost-intensive construction of shaping tools. The manufacture of samples on the 5-axis milling machine is fast and easy, allowing complex geometries.

As Managing Director of the family-owned company, Martin Sembach imposed high requirements on a 5-axis milling machine; the main criterion for acceptance was a high machine capability index Cmk even under extreme use of all axes. Collecting devices made of black zirconia were manufactured for experimental purposes. These will replace the metal ones installed in Sembach in-house sorting machines, as metal devices can cause higher rejection rates due to wear. However, the width of the groove in the collecting device is critical to functionality, as it must be manufactured with dimensions of 9.4 mm + max. 0.05 mm. At this point, the collecting device may not be smaller as this would not fit precisely. The milling machine allows small tolerances +/- 0.25 % without the need for complex hard machining.

The workpiece dimensions speak for themselves. The milling machine allows the production of small and complex components with raw part sizes ranging from 80 mm in diameter and 90 mm in height when using 5-axis milling and 300 x 270 x 1700 mm when using 3-axis milling. The sintered parts are a maximum of 70 mm in height with a maximum diameter of 60 mm using 5-axis milling technology and 250 x 230 x 135 mm using 3-axis milling machines.

“We are now able to produce demanding and complex parts without major expense and effort”, says Martin Sembach. Machining on 5 axes allows for flexible cutting movements. The workpiece can be moved not only in the three directions in space, but also in two other axes, which adds to flexibility. A single clamping allows the production of particularly difficult geometries. Prototyping or manufacturing of individual pieces used to be done manually and required much effort and intuition. The workpiece needed to be clamped on different sides and machined using grinding, drilling, turning and cutting in order to obtain a fully machined component. 5-axis machine milling is a subtractive manufacturing procedure replacing all these work steps with a single work step. Injection molding as well as dry pressing and extrusion are additive methods allowing complex geometries but requiring the construction of an appropriate tool beforehand. Costs very soon reach a five figure. Therefore, these methods are too inefficient to be used in manufacture of individual pieces and small batches.

Short machining times

Machining using the milling machine requires significantly shorter lead times than mold construction. The customer first provides a drawing or 3D data. The Sembach construction engineers enlarge these data to the correct proportions to compensate for the shrinkage of ceramics during sintering. The data are then exported to the CAM system and edited for use in the machine. The 5-axis milling machine can then machine the ceramic green body within a very short time. The sample part is sintered, tested and compared with the desired dimensions and requirements.

“Adding the production of individual pieces and small batches to our portfolio was the right decision”, states Martin Sembach, Managing Director of the family-owned business. A variety of opportunities opens up such as manufacture of small batches of decorative objects with aesthetically challenging designs or prototype manufacturing for the automotive sector. In addition, different materials are suitable for manufacturing in the milling machine ranging from the zirconia mentioned above to common aluminum oxide and high-frequency steatite.

Go to http://bit.ly/5achs-sembach to see how a ceramic component is machined on a 5- axis milling machine.