Thermal Treatment

Thermal treatment of ceramic components

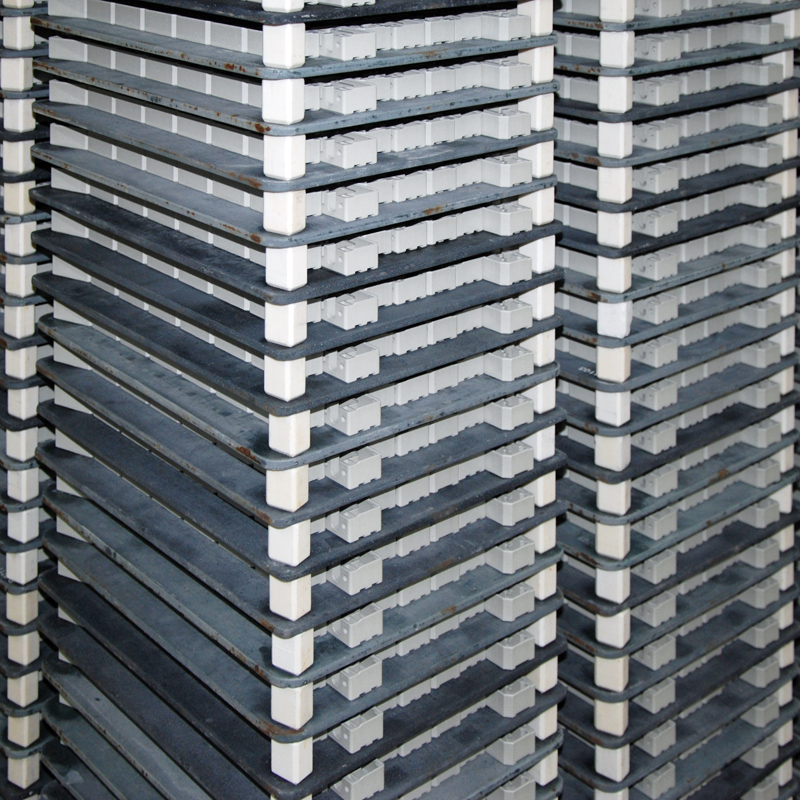

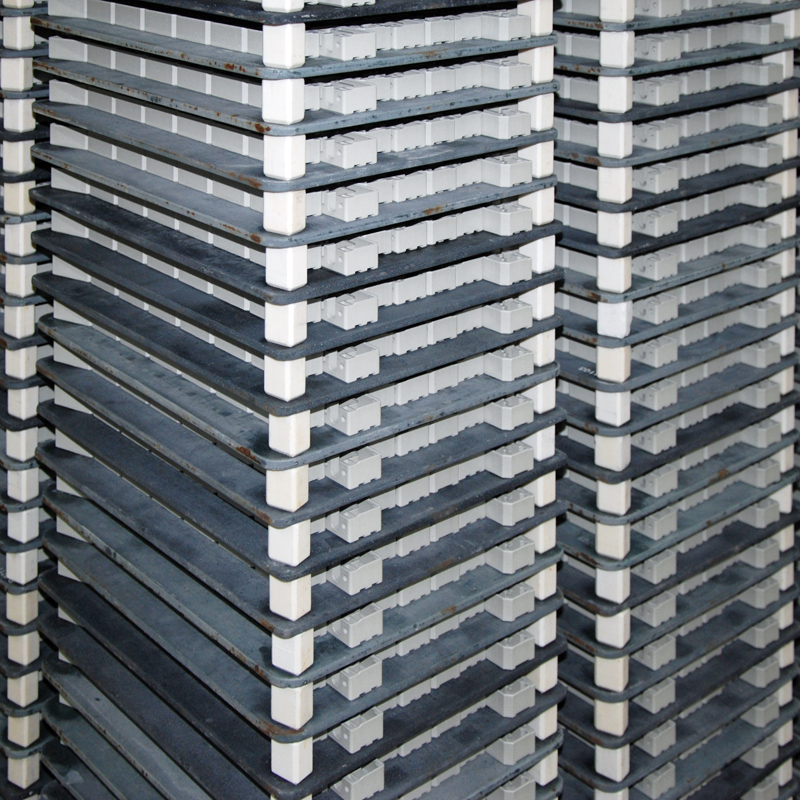

Thermal treatment comprises debinding and sintering; both are fully documented.

Debinding or pre-sintering of shaped bodies takes place at temperatures up to 1,100° C. During this process, the organic binder is removed carefully from the ceramic body and at the same time, the strength and edge stability is increased. We use 7 furnaces for this process.

Operating temperatures during sintering are between 1,200° C and 1,750° C. After debinding, this manufacturing step sinters the shaped ceramic parts. We are currently using 7 gas-fired front loading furnaces for sintering silicate ceramics. All process steps from loading to unloading are fully automated.

With thermal treatment, we attach particular importance to:

- Precise temperatures

- Constant furnace atmosphere

- High-quality sintering aids

We use 5 high-temperature furnaces up to 1,750° C for firing special ceramics such as alumina.